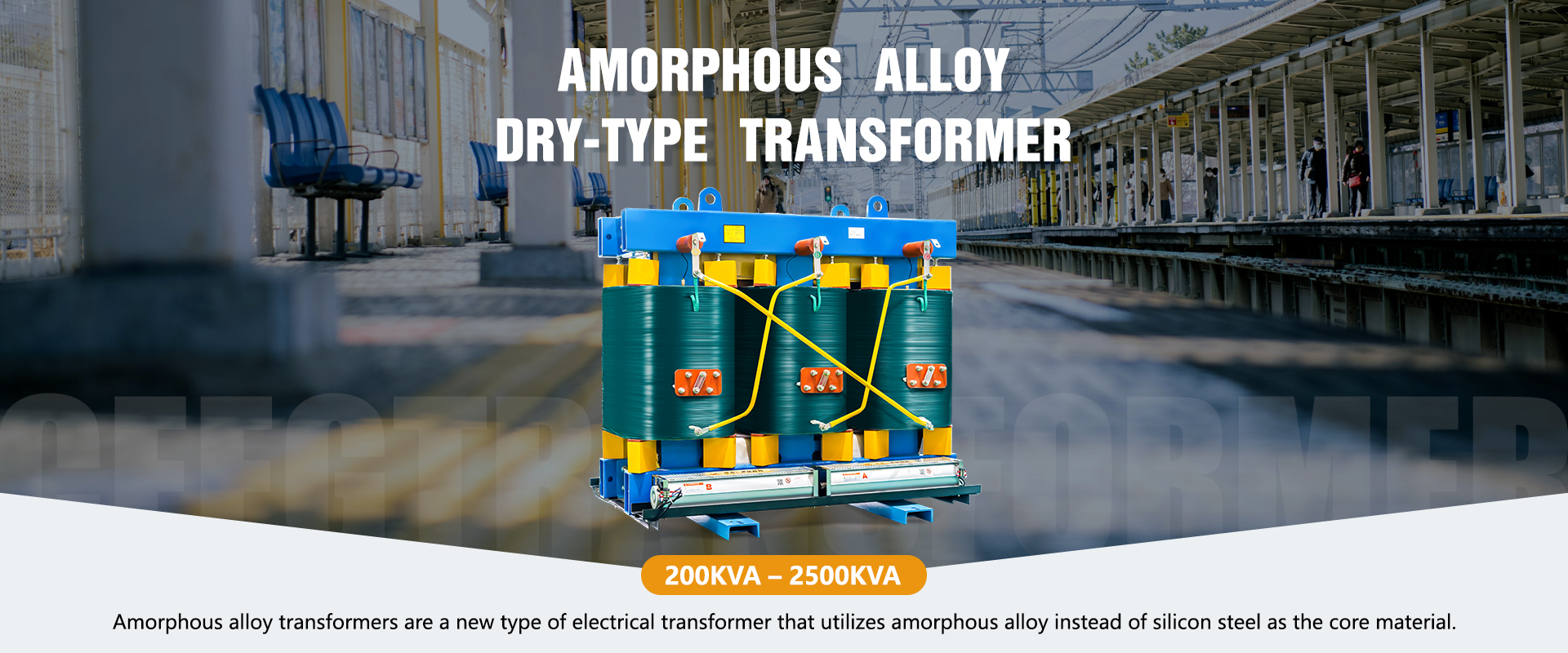

An amorphous alloy dry-type transformer is a new type of low-loss dry-type transformer. Its most significant feature is low no-load loss and obvious energy-saving effect. It can save a lot of power plant investment and reduce the consumption of power generation fuel, thereby reducing the impact on the atmospheric pollution environment.

Due to low loss, low heat generation, and low-temperature rise, the operating performance of amorphous alloy transformers is also very stable. CEEG's SCR(B)H15 series amorphous alloy products inherit the advantages of SG products such as good heat dissipation, no need for molds, and flexible design. At the same time, they draw on the SC product's barrel-type coils, which have good lightning impact resistance and longitudinal air channels in operation. It has self-cleaning characteristics and has been improved to launch an innovative generation of three-phase, three-column, and semi-encapsulated non-grade alloy dry-type transformers with energy-saving, safety, and environmental protection concepts.

CEEG's non-grade alloy dry-type transformers have a product capacity range of 30kVA~3150kVA and a voltage level of up to 35kV. It is currently a domestic manufacturer with relatively complete product capacity and voltage levels of non-grade alloy dry-type transformers.

Amorphous alloy strip

An amorphous alloy strip synthesizes iron, cobalt, carbon, silicon, boron, and other elements in a certain proportion. Under high-temperature melting conditions, it is cooled by a high-speed wheel at 10°C/S, so the metal has no obvious lattice interface.

.jpg)

.jpg!webp)